Foam & Tape Technologies

Forest City leverages a broad spectrum of advanced manufacturing processes to deliver lightweight foam components and precision-converted adhesive tape solutions, engineered to support efficient attachment strategies and meet evolving application demands.

-

Two-Dimensional Shapes

Process capabilities include skiving, die cutting, flash cutting, water-jet cutting, and laser cutting.

-

Three-Dimensional Shapes

Process capabilities include thermoforming, vacuum forming, injection molding, and 5-axis machining.

-

Laminating

Adhesive tapes are precision-laminated to foam, plastic, and metal substrates, with packaging options available in individual units or bulk formats on cards or reels.

-

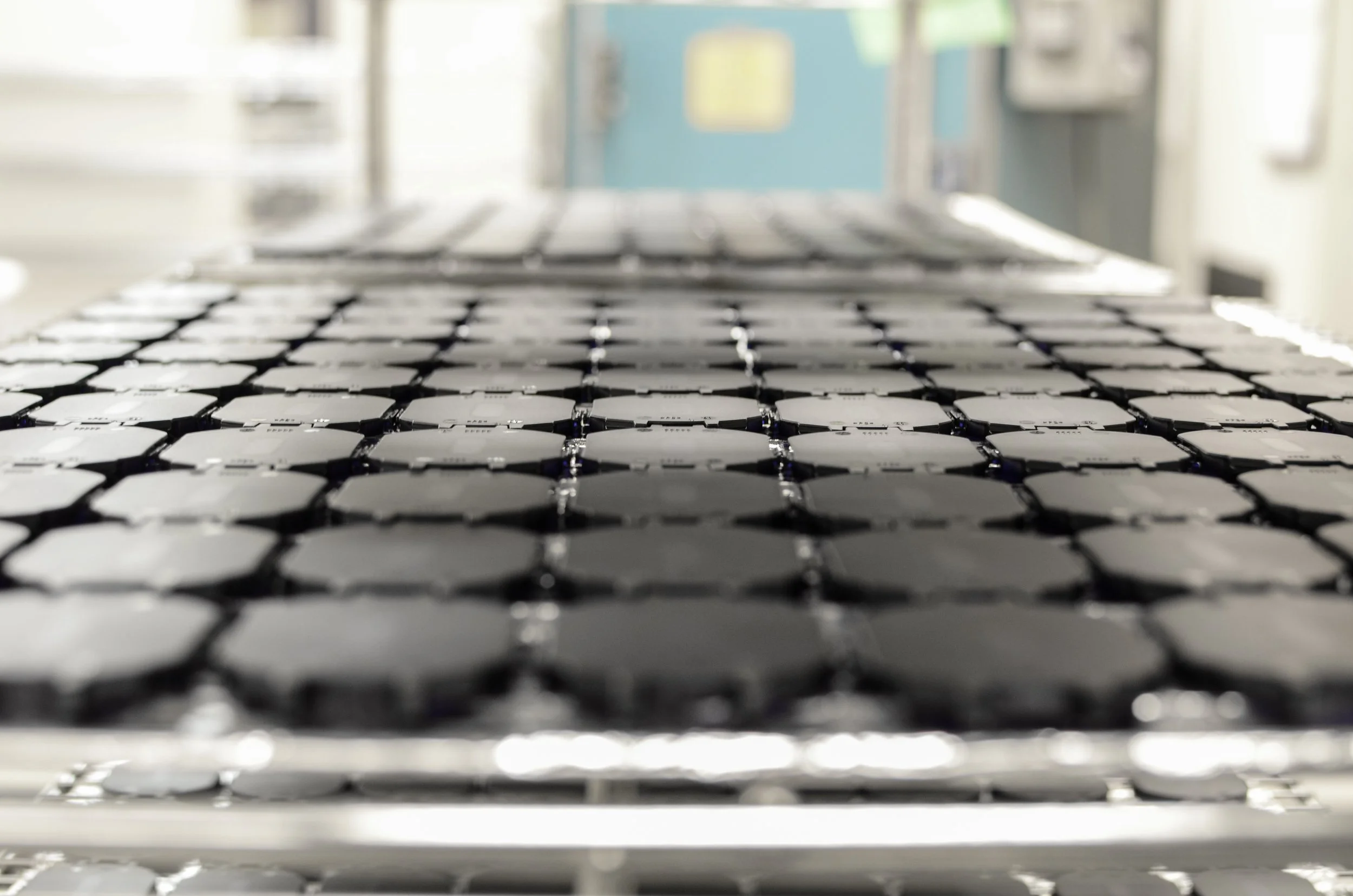

Structural Bonding

Specialists in the precision application of structural bonding tapes to diverse substrates, enabling high-strength, durable assemblies across demanding environments.

-

Lightweight Products

Engineered foam materials with high strength-to-weight ratios, molded into complex geometries to meet demanding structural and performance requirements.